Enhancements

January 20, 2022

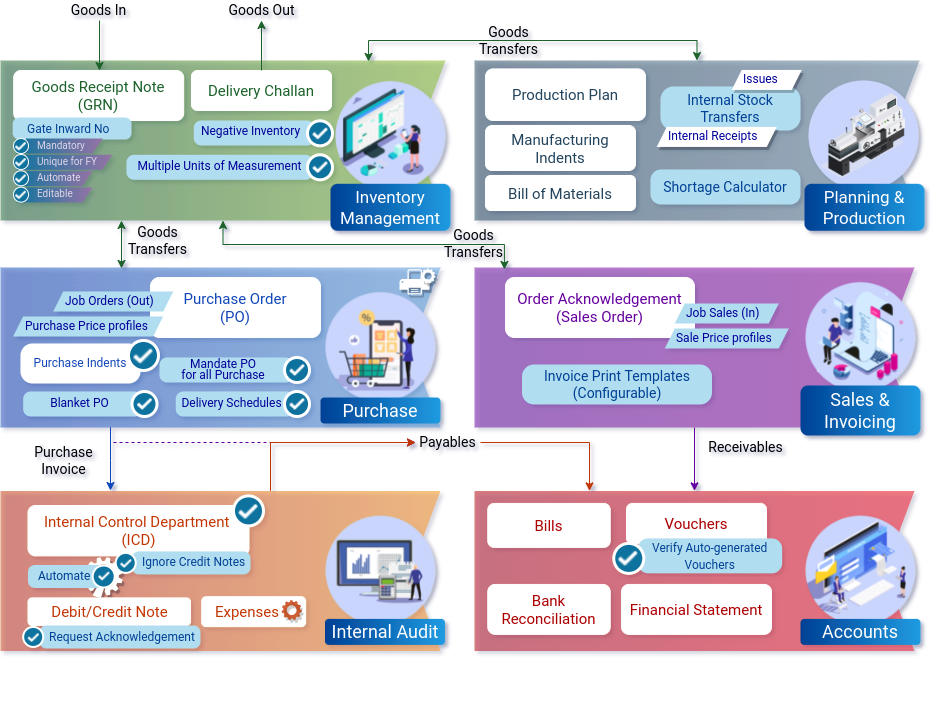

Production Planning & Management

Production Planning & Management is among the essential process for manufacturing and job processing organizations. This release delivers the base modules and features for such processes.

Objective : To provide base functionalities and modules that aid the manufacturing processes in terms of Production Planning & Management.

Features : The release introduces new modules in Manufacturing Indent and Production Plan. It also provides for Job Order creation from Manufacturing Indent. Most features are grouped under a new menu labelled Production found below Stores.

Manufacturing Indent (MI)

The purpose of Manufacturing Indent is to plan the Production quantity for

- Sale Orders (OA linked MI’s)

- Forecasts (stand-alone MI’s)

This document shall act as the quantity bound for the Production Planning which will be explained subsequently.

Field descriptions and purposes

- Purpose

- will be a simple text tag to capture a reason/purpose for MI’s created directly.

- will be a combination of Customer Name, OA No & Date for MIs created from an OA.

- Item selected from a type-ahead drop-down filter shall be marked for the production quantity planning.

- Required Qty, a numeric field, to capture the quantity that requires Production to be planned. Any change in this field shall display tick & cross buttons next to the field to save/reject the change

- OA Qty will be displayed for items populated from OA for reference

- Delivery Due, by default pulled from OA, or captured during MI creation (as Required Date) marks a deadline for the Item Production and Delivery

- MI No

- If MI Planned for an OA or a direct MI, its No & Date will be displayed

- If OA is not yet planned for production – display 2 buttons

- +, to create an MI with the Quantity entered in the

- NA, to mark the OA as MI Not Applicable. An ‘x’ mark will be available next to the NA tag enabling to reset the flag

Limitations: An OA shall be linked with only one MI, no matter how many Items form part of the OA.

Production Plan (PP)

This feature shall be compared with that of Job Order, only that the visualization of the feature has been optimized to suit the Production process.

Production Plan creation is not possible without creating an MI, i.e., only pending MI’s will be available to be translated into a PP.

It is possible to create Job Orders too from this screen/module (notice the external assignee). JO’s cannot be managed from here though.

Field description and purposes

- MI No, a type-ahead drop-down box that lists all pending Manufacturing Indent Number.

- Item, again a type-ahead drop-down, that lists all yet-to-be planned Items featured in the MI selected.

- Status section is where most action takes place. It provides for updating and tracking the Production Progress. It provides a colorful representation of the Update Progress

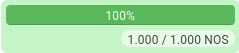

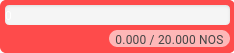

- For example, the plan that was Completed On-time shall be represented as the green one below while Overdue with no progress is represented as the red one below while

-

- It covers both Status and Timeliness of the progress, as found below

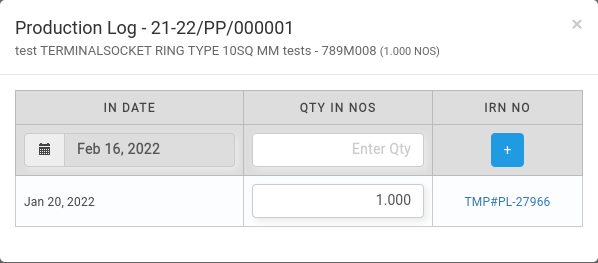

- Progress can be updated in the pop-up that opens when clicking on the status section which is basically a list of IRNs created against this PP, which will be subjected to scrutiny by the Stores.

- It covers both Status and Timeliness of the progress, as found below

- Schedule captures the timeliness of the plan, by binding a date-range

- Assigned To, a type-ahead drop-down, identifies the person/department/vendor the Production task is assigned to.

- PP No displays an auto-generated once a plan is created, which will be used for all further reference & identification of this document. It is serialized and starts over every FY.

Other activities possible in this module for each line item are Edit, Preview, Remarks, Change log, Item Usage & Returns & Short-close found as hover icons against every row, as shown below![]()

Other Related Changes

Few menu items were re-arranged and renamed as listed below

- The sub-menu items Issue , Issue Return , Job-In Stock Register , Job-Out Stock Register , Shortage List are moved under the new menu Production.

- Indent menu item is now renamed as Purchase Indent and moved from the Stores section to the Purchase section.Few of the Menu items are re-arranged and re-named as listed below

- Job Order was listed as an exclusive Item under the Purchase menu. It is no longer part of Purchase Order. JO creation will be possible from both PI’s & MI’s, whereas PO creation shall be possible only from PI.